Minimizing our environmental impact on air, water, and soil is a critical component of the safe production and transportation of methanol, and an important part of our commitment to Responsible Care.

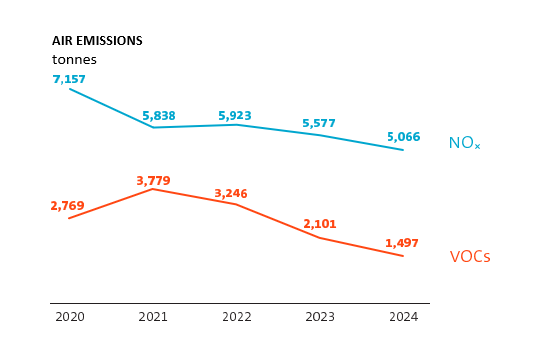

Reducing impacts on the environment from air emissions

Good air quality is fundamental to human health and well-being. Air quality is measured by the concentration of pollutants in the air, including nitrogen oxides (NO×), sulphur oxides (SO×) and volatile organic compounds (VOCs) such as methanol vapours. We follow local regulations, and we aim to reduce emissions associated with our manufacturing operations and our Waterfront Shipping division that could impact local air quality and our neighbouring communities.

We have programs in place to minimize any negative impacts to water and soil associated with our manufacturing and Waterfront Shipping operations. By preventing spills and managing water discharges, we work to minimize the effects that our operations have on the environment and the communities around us.

Reducing impacts on the environment from manufacturing

Through water discharge monitoring and spill prevention and response readiness, we aim to minimize our impact on the surrounding environment.

| Water discharge monitoring | Our manufacturing sites use water in several stages of the production process. Wastewater generated from production is treated in accordance with local requirements and analyzed before we safely discharge it back into the environment or to municipal services |

| Spill prevention and response readiness | Given the nature of our operations, the potential for impacts to water or soil is related to accidental spills from our manufacturing facilities including spills of methanol, water treatment chemicals or petroleum fuels and lubricants for machinery on-site. To prevent releases, we have controls and containment measures in place, along with a comprehensive spill monitoring and prevention program |

Reducing impacts on the environment from Waterfront Shipping

Through spill prevention measures, managing our water discharges, and making efforts to reduce our impacts on marine life, we responsibly operate our Waterfront Shipping vessels.

| Spill prevention | In the unlikely event of an accident, all Waterfront Shipping vessels have double hulls and secondary deck containment to help prevent product from reaching the environment and marine life. We have strict vessel loading guidelines and use best practices to prevent spills during loading and discharging. |

| Ballast water management | All vessels in the Waterfront Shipping fleet have ballast water exchange plans that significantly reduce the risk of harmful aquatic organisms or pathogens. |

| Low-sulphur fuel | Waterfront Shipping uses low-sulphur fuel (including methanol) in 97 per cent of its vessel hours. |

| Tank cleaning practices | All of our dual-fuel ships use methanol for tank cleaning. Running methanol through the tank cleaning equipment replaces the need to use bleach or other solvents and reduces tank entries by workers, which improves safety, and the resulting methanol can still be used as fuel in the engine. |

To learn more, please visit pages 45 to 47 of the 2024 Sustainability Report.

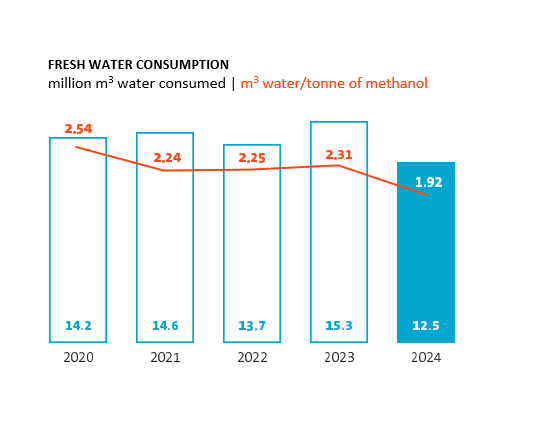

Water use in manufacturing

We depend on water for our operations and share this vital resource with the communities where we operate. Through our water stewardship program, we focus on minimizing our water use and protecting water quality in our areas of operation. While water is crucial to the production of methanol, we understand the importance of good water stewardship programs that focus on minimizing the use of water across our manufacturing facilities.

| Most of the water used in our manufacturing is used in cooling systems to remove heat, but a portion is also used to heat processes and is consumed as steam during the manufacturing process. Eighty per cent of the water we withdraw is seawater from two sites (Chile and Trinidad and Tobago). Our other four sites that rely solely on fresh water have designs that minimize water withdrawals and help us conserve fresh water. By working to understand water risks, optimizing chemical use, and improving water efficiency, we aim to optimize our water consumption at each of our manufacturing locations. |  |

Minimizing waste

Responsible and safe management of waste streams is essential to being a responsible company. At Methanex, we strive to minimize waste at the source or recycle or reuse where possible. We remain committed to minimizing the environmental impact of our operations following the principles of Responsible Care and continue to review and improve our waste management practices. We work to reduce the waste during our regular operations and during major projects, such as turnarounds. We place particular emphasis on the safe and responsible management of hazardous waste.

| Managing waste from manufacturing | Our manufacturing facilities produce minimal waste during regular operations, because the major raw material needed to produce methanol (natural gas or other feedstock) is consumed. |

| Managing waste from turnarounds | Most of our waste volume is generated during major maintenance turnarounds, plant refurbishments and servicing work. We have strict procedures in place to verify that the waste is properly segregated, classified and the correct disposal options are established. |

To learn more, please visit pages 44 to 51 of the 2024 Sustainability Report.