We have comprehensive health and safety programs to protect the safety of our team members and contractors. Our goal is to do the right thing, the right way, every time.

Fostering Safe Behaviours & Focusing on Critical Activities

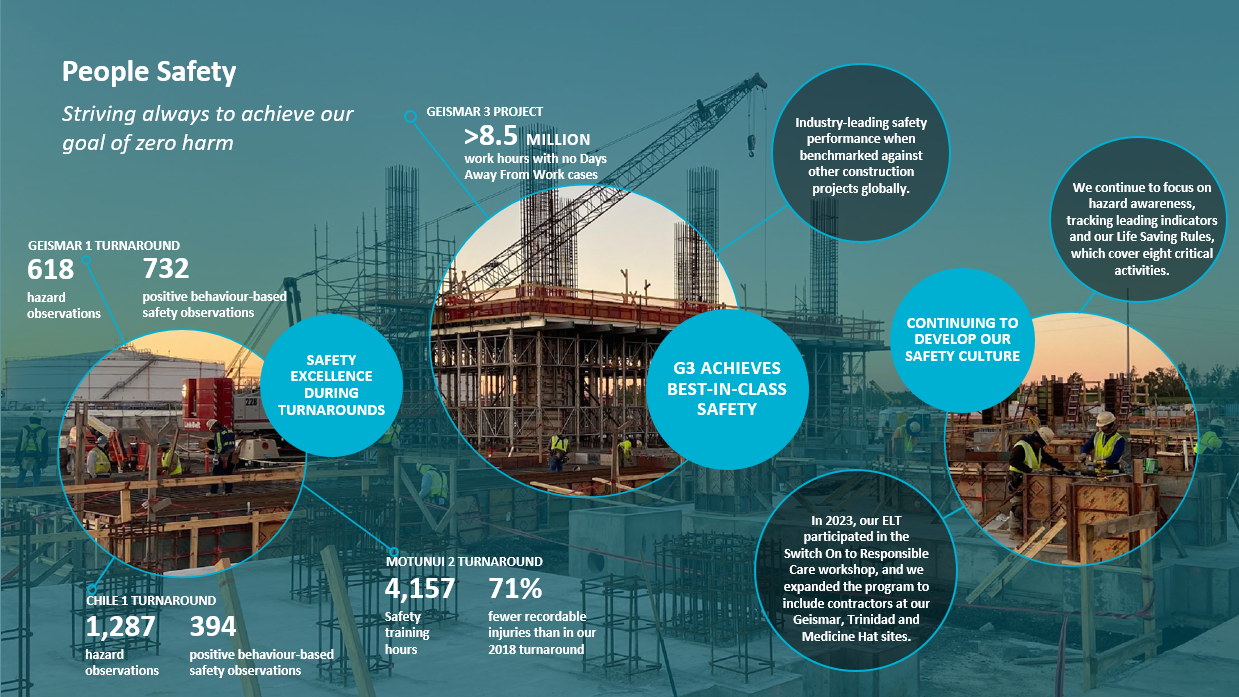

A key safety result in 2023 occurred at our Geismar 3 project. We managed a complex construction environment beside two operating methanol plants, had a peak workforce of more than 1,800 people, faced record high summer temperatures, and our team completed an impressive 8.5+ million work hours with no injuries that resulted in Days Away From Work. These safety results were best in class, ranking in the top quartile of major construction projects.

Safety is critical across our business, particularly at our manufacturing sites, where more than 75% of our employees work. New employees at our manufacturing sites participate in a Switch On to Responsible Care workshop after joining the company and employees receive regular refresher sessions. In 2023, Methanex continued to drive strong safety performance through three major turnaround projects around the globe.

Maintaining Hazard Awareness & Tracking Leading Indicators

As part of our proactive approach to building our safety culture, we track leading indicators to measure team member engagement. We track leading indicators to measure team member engagement as part of our approach to building our safety culture where employees feel empowered to contribute.

We consider near-misses – events that did not have a negative outcome but could have – to be learning opportunities that help prevent future incidents.

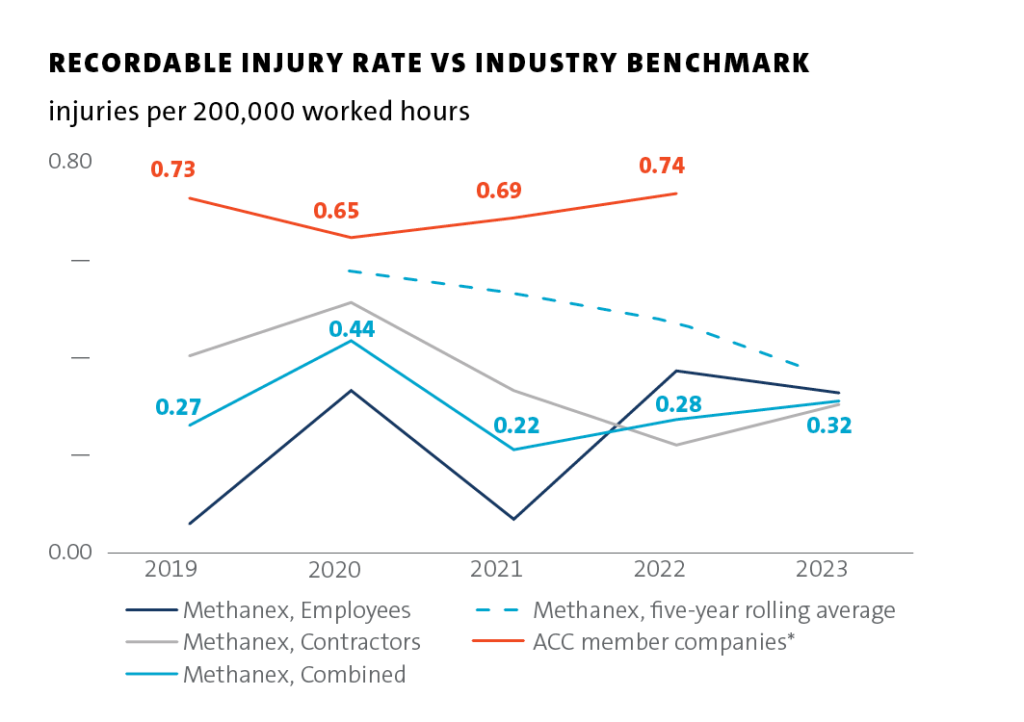

*Source: American Chemistry Council

Our five-year rolling average continues to decline thanks to our safety practices. Our recordable injury rate is consistently lower than the average of the chemical company members of American Chemistry Council.

Process Safety

Our commitment to Responsible Care is unwavering. We work every day to put our values and safe practices into action to ensure the safety of the employees, contractors, visitors and communities near our operations.

We contain our process safety risks through a combination of risk reduction measures known as “safeguards”. These include an Executive Process Safety Steering Committee reviewing our performance and execution of strategic improvement plans, reviewing our global process safety program against industry best practices, and a focus on 10 process safety fundamentals highlighting critical activities and behaviours for preventing incidents.

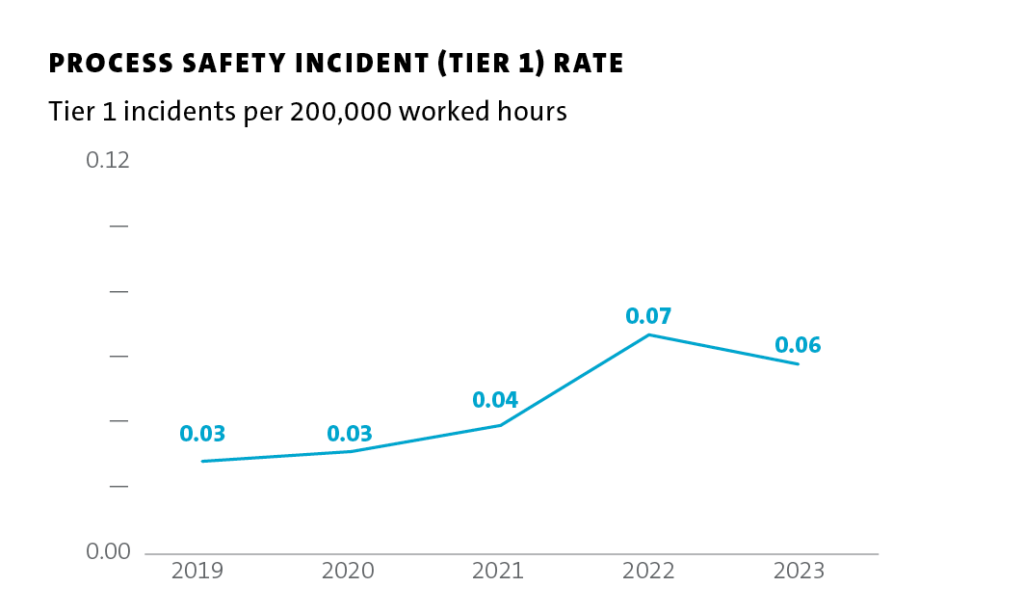

Our focus on hazard prevention and high-quality incident reviews by leadership has helped us maintain a low rate of one to two Tier 1 process safety incidents per year in the last five years.

Protecting Air Quality

Good air quality is fundamental to human health and well-being. In alignment with local regulations, we continually work to reduce emissions that could impact local air quality and our communities.

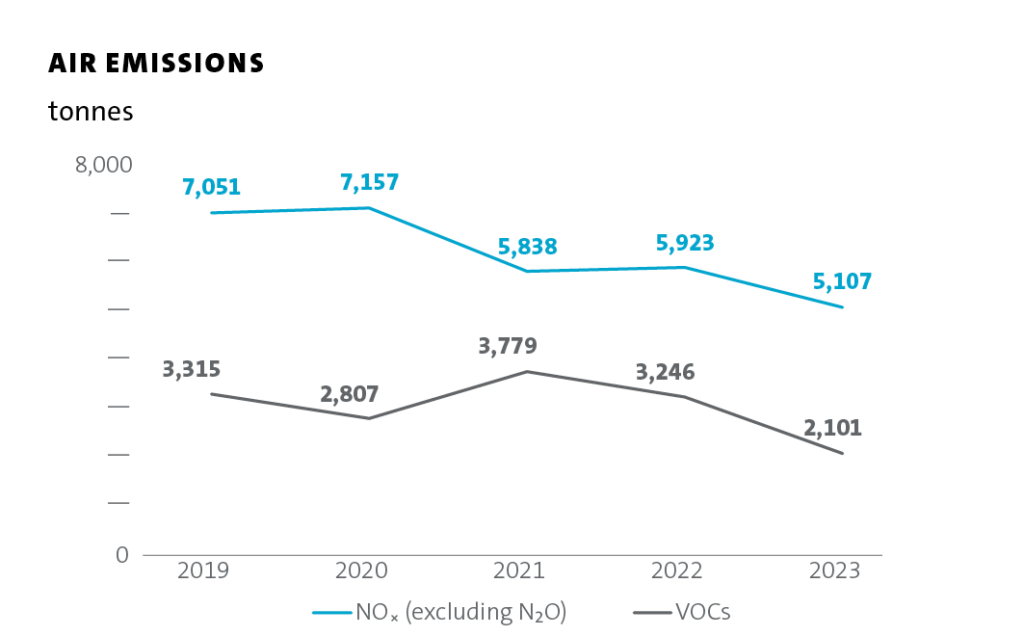

Air quality is measured by the concentration of pollutants in the air, including nitrogen oxides (NO×), sulphur oxides (SO×) and volatile organic compounds (VOCs) such as methanol vapours and methane. Changes in NOx and VOC emissions are closely linked to production levels in our asset mix. Overall, NO× emissions have decreased over the last five years, largely due to the installation of lower-NO× burners at one of our plants with older reforming technology.

Water Stewardship

Through our water stewardship program, we focus on minimizing our water use and protecting water quality in our areas of operation. Because fresh water is a shared natural resource with our communities and the environment, we put the bulk of our water stewardship efforts into conserving and protecting freshwater sources. This is particularly important in regions with potential for freshwater scarcity such as our Damietta, Egypt site.

To maximize efficiency and return as much water to the environment as possible, our facilities have water conservation procedures to minimize, reuse and recycle water. For example, almost all our production facilities reuse process condensate in different phases of the production process, and over half of our sites reuse the wastewater from distillation columns, reducing the overall volume of water we need to withdraw.

To read more about how we protect water quality, understand our water risk, and improving water efficiency, please see pages 47 to 48 of the 2023 Sustainability Report.

Spills & Releases

Methanex safely manages large volumes of liquid chemicals every day. We have rigorous controls and containment measures in place, along with a comprehensive spill monitoring and prevention program. We have had zero significant environmental spills and releases in 2023.

To read more about how we prevent, monitor, and respond to spills, please see page 49 of the 2023 Sustainability Report.