Employee and contractor safety

Safety is critical across our business, particularly at our manufacturing sites, where more than 75 per cent of our employees work. Our number one priority is ensuring every team member gets home safely every day.

We take a unified approach to employee and contractor safety. Contractors are responsible for more than 50 per cent of total worked hours due to their role in turnarounds, large capital projects and ongoing activities. Our goal to be a zero-harm workplace is only achievable with their active participation. Through employee and contractor engagement, maintaining a focus on hazardous and critical activities and focusing on occupational and industrial hygiene, we work to uphold high safety standards across all our worksites.

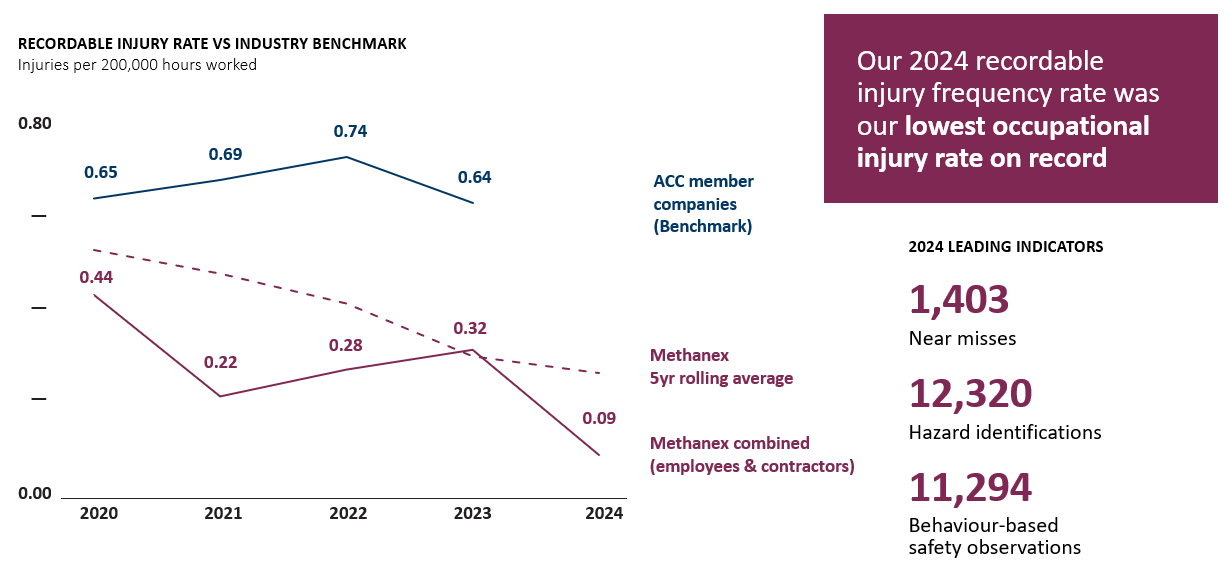

We invest considerable effort and resources to pursue safety excellence across all regions. Through focusing on critical activities and empowering workers to speak up and take an active role in safe work, we work to protect the well-being of workers at our sites. We have seen a significant drop in our recordable injury rates which we attribute to continuous focus on promoting constant hazard awareness and regular engagement.

We invest considerable effort and resources to pursue safety excellence across all regions. Through focusing on critical activities and empowering workers to speak up and take an active role in safe work, we work to protect the well-being of workers at our sites through:

- Focusing on critical activities

- Promoting a strong safety culture through training

- Engaging with our employee and contractors on safety

- Listening to employee concerns

To learn more, visit pages 53 to 56 of the 2024 Sustainability Report.

Process Safety

We work every day to put our values and safe practices into action to ensure the safety of the employees, contractors, visitors and communities near our operations.

Process safety management is designed to prevent incidents from occurring by using both technical engineering controls and operations management, maintenance programs and the management of change to contain process-related hazards safely and reliably. We contain our process safety risks through a combination of risk reduction measures known as “safeguards.” These safeguards take the form of:

- Designing safe plants and physical infrastructure

- Maintain and operating our assets

- Assessing the competency of our workers and leaders

Fostering a culture of continuous improvement

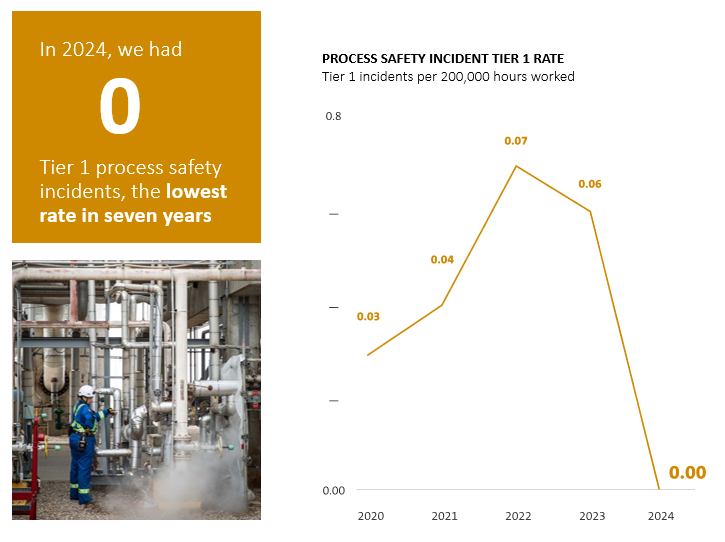

A key part of our culture is our willingness to learn and improve our processes, which is particularly important when it comes to process safety events. As part of this commitment, we conduct thorough incident investigations and conduct targeted process safety campaigns.

| Incident reviews | Due to their potential for catastrophic impacts, we report all process safety near misses and events. All serious and major process safety events (incidents that have the most severe negative impacts on people, the environment, or to our business or reputation) undergo a full root cause analysis. |

| Process safety fundamentals | To place a renewed focus on looking critically at basic activities, in 2024, we conducted a year-long Process Safety Fundamentals campaign for all staff at our manufacturing sites focused on measures to reduce the likelihood of process safety events |

| Preparing for emergencies | Our ability to respond effectively to disruptions is essential for safe, continuous operations during a crisis or disaster. We have crisis management plans and crisis management teams in all regions. Our crisis management plans cover scenarios including extreme weather events, pandemics and process safety events. |

Our focus on hazard prevention and high-quality incident reviews by leadership has helped us maintain a low rate of process safety incidents in the last five years.

To learn more, visit pages 57 to 59 of the 2024 Sustainability Report.

Product Stewardship

Product stewardship involves managing human health and environmental risks throughout the lifecycle of a product. This includes the safe handling and transportation of methanol. Like many other chemicals and fuels, methanol is flammable and can be toxic if swallowed or inhaled. To keep people and the environment safe, appropriate safety precautions must be taken when using, handling or working around methanol.

Our commitment to product stewardship encompasses both safe handling by our own workers and verifying that high safety standards are in place at distribution sites. At our manufacturing sites, methanol is stored in tanks and transported via pipelines into marine vessels or loaded into railcars or trucks. As part of our marketing and logistics service, we load and distribute methanol by vessel at 117 terminals around the world (five at our manufacturing sites, 30 leased terminals and 82 at customer or third-party locations).

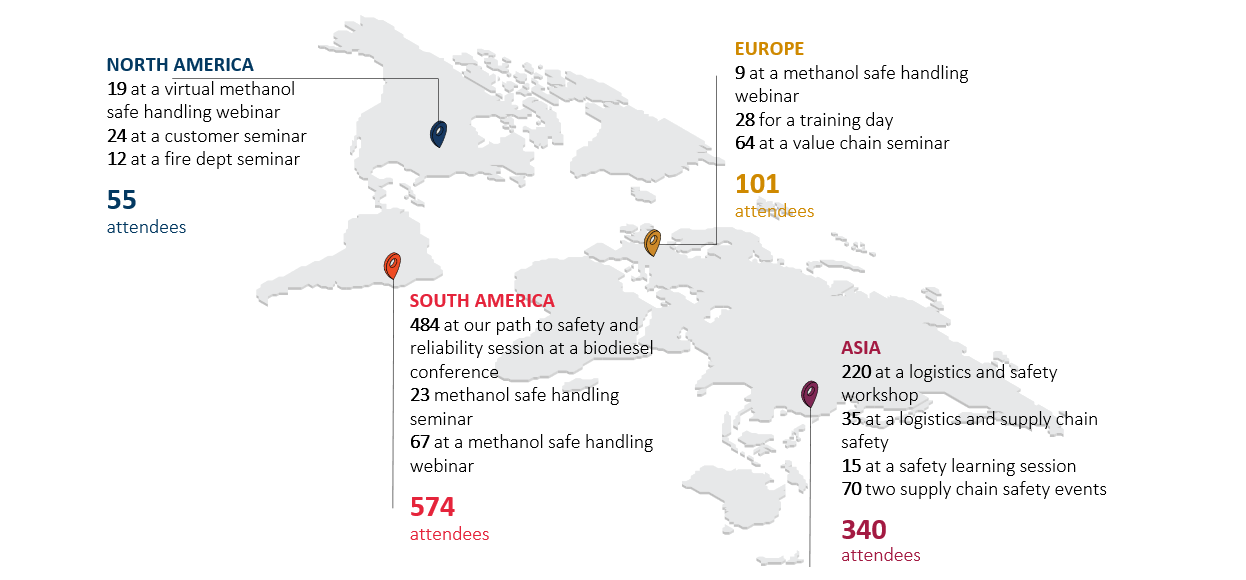

Promoting methanol safety

We promote safe handling practices for methanol not only in our organization, but externally across the globe. This includes reassessing all our contracted terminals using the Chemical Distribution Institutes Terminal inspection every three years. We use our decades of experience to help educate customers, distributors and logistics partners on topics such as safe handling, barge inspections, emergency response drills and training, fire safety, and road safety.

To learn more, please visit pages 60 to 63 of the 2024 Sustainability Report.